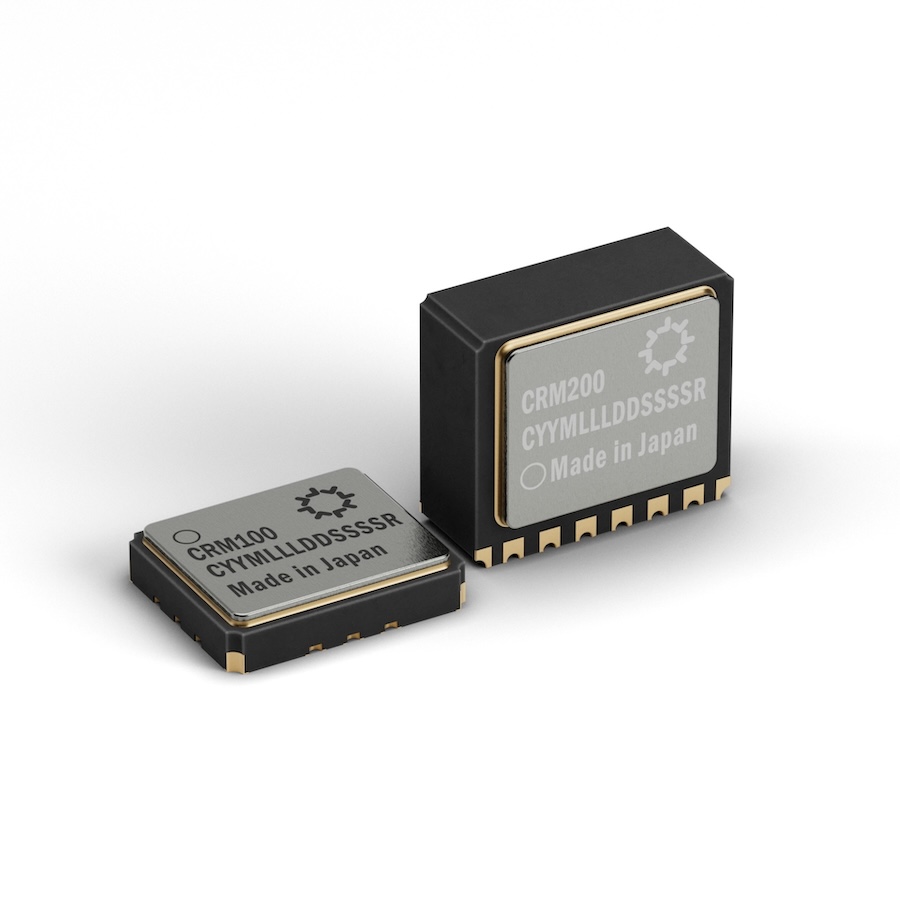

Silicon Sensing provides a comprehensive portfolio of accelerometers and gyroscopes that support both off-the-shelf and custom inertial measurement unit (IMU) solutions, making the company a relevant partner in the discussion around whether to purchase or internally develop an IMU.

As motion sensing continues to underpin critical operations in marine research, robotics, autonomous navigation, and industrial automation, the decision to buy or build an IMU is a pivotal one for many engineering teams. Read more >>

IMUs serve as the core sensing element in systems requiring stabilization, navigation, or motion tracking. Their applications are broad, ranging from underwater operations without GPS access to guidance in automated manufacturing environments. This functional versatility has made them integral to fields that rely on precise orientation and movement data.

In-House Development: Flexibility at a Cost

Developing an IMU internally offers theoretical benefits, including sensor-level customization and reduced component costs. With accessible components such as gyroscopes and accelerometers, affordable development boards, and open-source software libraries, the appeal lies in tailoring the unit to project-specific performance parameters. Teams may combine sensors from various vendors to achieve unique capabilities not offered by pre-integrated solutions.

However, building a functional and reliable IMU is resource-intensive. Accurate performance across key parameters such as bias instability, scale factor consistency, and thermal behavior requires extensive calibration. This process involves the use of high-grade equipment, including thermal chambers, vibration test platforms, and precision turntables. Moreover, successful calibration demands environments isolated from structural vibrations and ambient noise, factors that add considerable infrastructure requirements.

Beyond physical setup, substantial investment in algorithm development and sensor fusion expertise is also necessary. Without this depth of capability, achieving a stable and robust solution becomes increasingly difficult. As such, while building an IMU may suit academic institutions or research-driven programs, the approach is rarely optimal for organizations aiming for dependable performance under commercial or operational constraints.

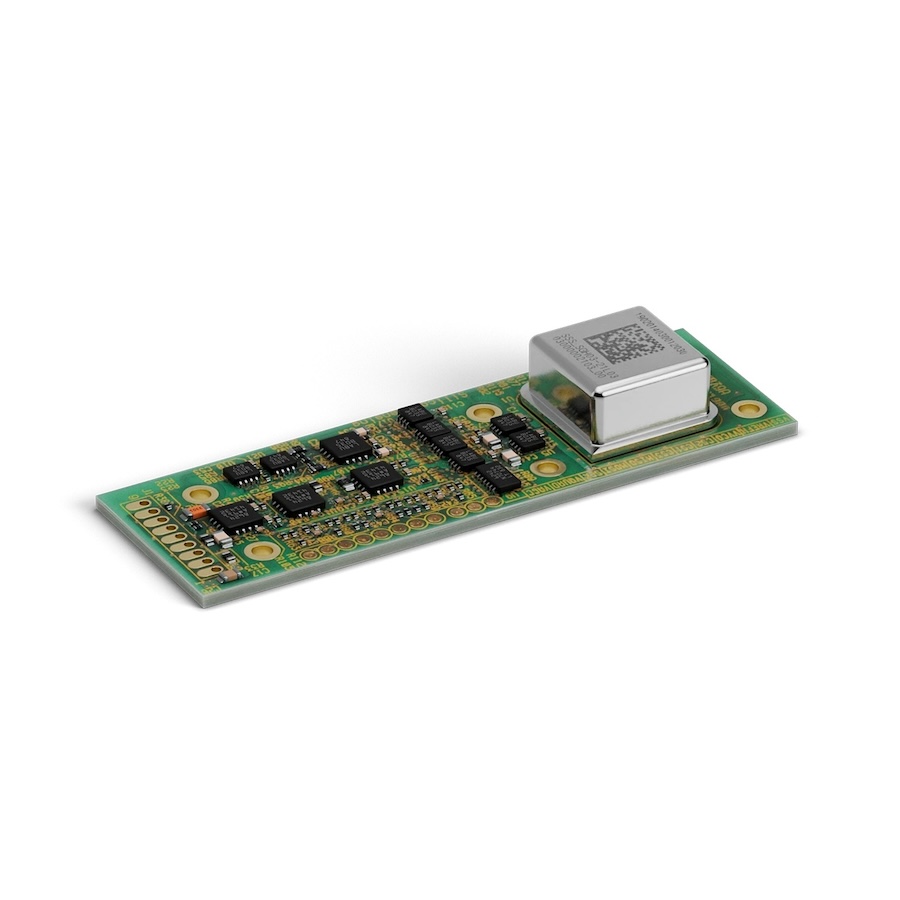

For those opting to pursue custom development, suppliers like Silicon Sensing mitigate integration risks by offering sensor components engineered for compatibility in interface and performance. This alignment simplifies design, accelerates development, and reduces the likelihood of unforeseen integration issues. Equally important, experienced sensor providers can offer guidance across the design and qualification lifecycle, from specification through to calibration and environmental testing.

Commercial IMUs: Streamlined Integration and Verified Performance

Alternatively, acquiring a commercially available IMU streamlines the development process by removing the need for sensor calibration, mechanical design of test fixtures, and software integration from multiple component vendors. This accelerates system-level development and allows engineering efforts to remain focused on higher-level project deliverables.

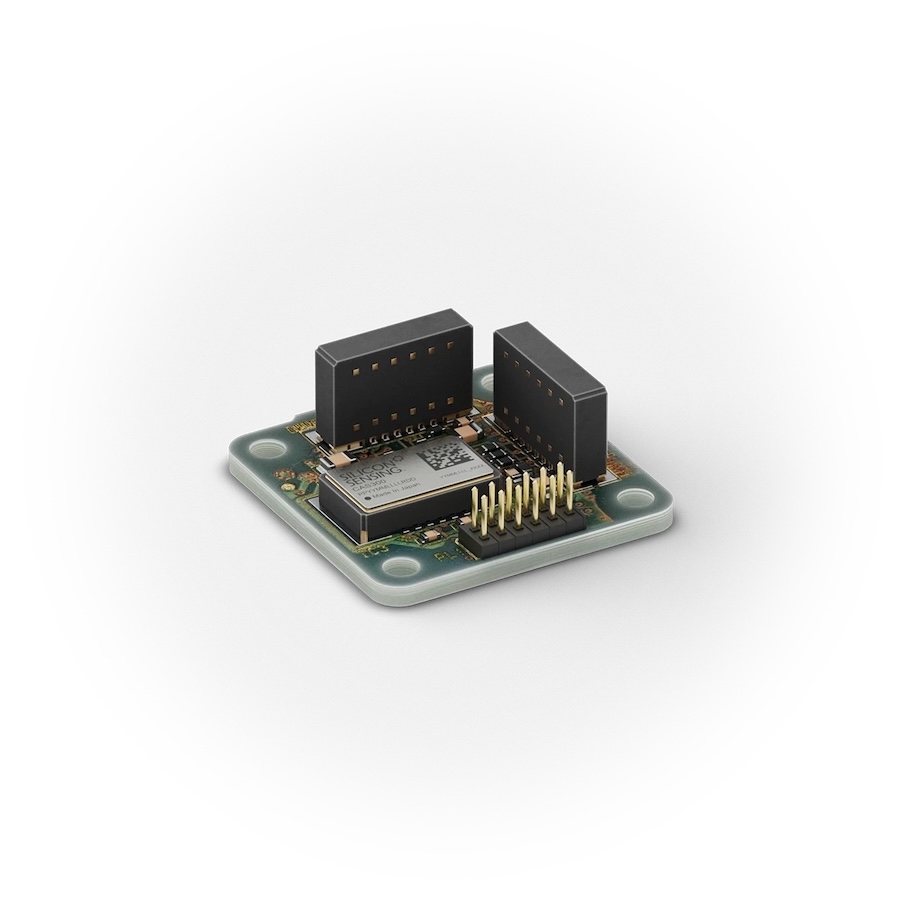

Products such as the DMU41 from Silicon Sensing illustrate the advantages of commercial IMUs. The unit incorporates a matched suite of sensors pre-calibrated for low bias instability, consistent scale factor, and thermal resilience. Each IMU undergoes extensive environmental qualification prior to shipment, ensuring predictable behavior under a range of conditions. This pre-deployment assurance reduces the verification workload during system integration and improves deployment timelines.

While commercial IMUs may restrict configurability, such as fixed data output rates or defined communication protocols, modern units are typically designed with flexible operational envelopes to accommodate a wide range of use cases. Nonetheless, in scenarios demanding bespoke data handling or system-level integration beyond conventional design limits, a custom approach may still be warranted. In such cases, the availability of field-proven sensor components from a single manufacturer, such as Silicon Sensing, helps reduce development uncertainty.

Strategic Decision-Making

Deciding between building and buying an IMU hinges on project requirements, development timelines, available resources, and long-term maintenance considerations. Teams focused on product delivery, cost control, and operational reliability generally benefit from off-the-shelf units, while those aiming for experimental freedom or unique integration challenges may find value in in-house development.

In either case, working with a supplier that offers both individual inertial sensors and complete IMUs, supported by technical expertise and cohesive design principles, delivers long-term advantages. It reduces development risk, enhances compatibility across components, and supports scalable performance from prototype to deployment.

Read more about this topic, or contact Silicon Sensing to discuss your specific project needs.