Suppliers

Add your company

Precision Optical Components for Underwater Imaging & Subsea Systems

If you design, build or supply Optical Components, create a profile to showcase your capabilities on this page

Optical Components, lenses, windows, and domes for ROVs and Marine Applications

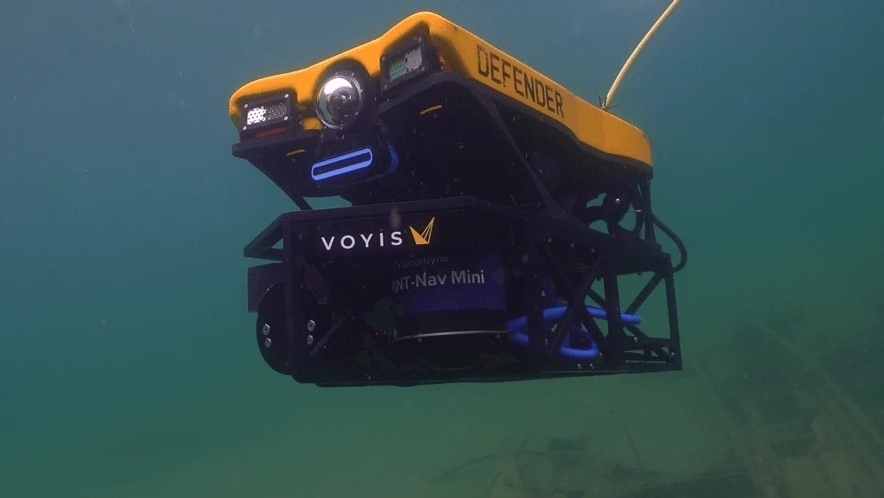

Precision optical components support critical functions in subsea and marine environments, particularly remotely operated vehicles (ROVs), autonomous systems, and underwater imaging platforms. These components include lenses, windows, and domes designed to protect sensitive optics and electronics while preserving image fidelity and operational visibility under extreme pressure and in corrosive saltwater conditions.

Materials such as borosilicate glass, sapphire, quartz, and acrylic are commonly selected for their mechanical strength, chemical resistance, and optical clarity. Coatings such as antireflective (AR), hydrophobic, and scratch-resistant layers further enhance the durability and performance of these components.

Applications and Use Cases

Optical components are vital across a range of marine applications, each demanding specific design and material considerations:

ROV Cameras and Imaging Systems

High-resolution subsea camera systems rely on precisely shaped and coated lenses and ROV domes to deliver real-time video for inspection, repair, and environmental monitoring. The field of view, distortion characteristics, and mechanical alignment of these optical components have a significant impact on mission success.

AUV Navigation and Mapping

Autonomous underwater vehicles require compact optical windows and domes that support stereo cameras and imaging sonar, ensuring accurate data collection during bathymetric mapping and subsea infrastructure inspection.

Environmental Monitoring Platforms

Systems equipped with spectrophotometers and photomultiplier tubes use UV-transparent quartz windows to detect changes in water chemistry and light absorption at various depths.

Marine Biology Observation

Aquaculture ROVs and research platforms monitoring coral reefs, fish behavior, or bioluminescent organisms use hemispherical domes and low-light lenses to capture high-fidelity imagery with minimal intrusion.

Subsea Oil and Gas Infrastructure

Inspection-class ROVs and deep-sea tools often include optical ports sealed with high-strength glass or sapphire windows that can endure pressures beyond 6,000 meters of depth.

Underwater Archaeology and Surveying

Optical lenses and domes are combined with laser line scan and photogrammetry to reconstruct submerged sites and artifacts digitally.

Types of Optical Components

Optical Lenses

Underwater lenses must balance performance in air with underwater performance, where the refractive index changes. Common configurations include:

- Plano-Convex Lenses: Provide a positive focal length and are ideal for collimating light from point sources.

- Plano-Concave Lenses: Feature a negative focal length for beam expansion or image correction.

- Meniscus Lenses: Combine convex and concave surfaces to reduce spherical aberration, often used in wide-angle imaging.

- Curved Lenses and Domed Front Elements: Adapted for high field-of-view underwater cameras and fisheye objectives.

- Design considerations must also account for chromatic aberration, coating durability, and mounting alignment within housings subjected to hydrostatic pressure.

Optical Windows

Optical windows act as barrier components, separating the sensor or imaging element from the external marine environment. Types include:

- Flat Windows: Offer minimal optical distortion when oriented perpendicularly to the line of sight; ideal for 2D sensors.

- Domed Windows: Reduce drag and provide an undistorted view over wide angles, commonly used for ROV camera systems.

- Tapered or Aspheric Windows: Engineered to correct for refraction or improve laminar flow around sensing systems.

- Optical Port Assemblies: Include sealing flanges, gaskets, and sometimes index-matching gels to maintain clarity and integrity at depth.

Window thickness is a critical factor in pressure resistance. Thicker windows or laminated assemblies may be required for operations at full ocean depth (>8,000 meters) while maintaining transmittance.

Optical Domes

Dome-shaped optics support panoramic or hemispheric views with minimal edge distortion. These are essential for:

- 360-Degree Imaging: Used in photogrammetry and underwater robotics navigation.

- Wide-Angle Cameras: Hemispherical domes extend the field of view while minimizing light bending due to refraction.

- Bio-Inspired Optics: Mimic natural visual systems like fish or cephalopods for ecological research or stealth monitoring.

Domes must be precisely machined and polished, with consistent wall thickness to prevent image warping. Optical-grade acrylic and borosilicate are selected based on weight and depth requirements.

Coatings and Surface Treatments

Optical component coatings are critical in marine applications for maintaining clarity and longevity:

- Antireflective (AR) Coatings: Reduce surface reflection losses, often with multi-layer dielectric stacks optimized for underwater lighting.

- Hydrophobic Coatings: Promote water beading and runoff, keeping lenses clear of salt spray and condensation.

- Oleophobic Coatings: Resist oils and biofouling agents, especially useful in long-duration deployments.

- Scratch-Resistant Coatings: Protect from mechanical abrasion due to sediment, marine life, or handling during recovery.

- Anti-Fog Treatments: Used in sealed enclosures where temperature gradients may cause condensation, preserving image quality during rapid deployment.

Emerging coatings include nanostructured surfaces that mimic biological anti-fouling mechanisms, offering passive protection without environmental harm.

Material Properties and Selection

Material choice directly impacts optical, mechanical, and environmental performance. Key considerations include:

- Borosilicate Glass: Balances cost, machinability, and optical performance. Resistant to thermal shock and chemical corrosion.

- Sapphire: High hardness and compressive strength suit extreme depths and abrasive environments. Transmits from UV through IR.

- Quartz: Offers superior UV transmission and thermal stability. Used in spectroscopic and environmental monitoring.

- Acrylic: Lightweight and impact-resistant, with moderate pressure capabilities. Suitable for shallow to mid-depth platforms.

- Polycarbonate: High impact strength and flexibility; used in lower-cost, ruggedized housings or protective overlays.

Engineering and Integration

Precision machining and sealing are essential for ensuring the long-term integrity of optical systems underwater:

- Flanges and Gaskets: Must accommodate pressure cycles and thermal expansion without compromising the seal.

- Optical Adhesives and Cements: Index-matched adhesives minimize internal reflection and support lamination of multi-element optics.

- Index-Matching Fluids: Used between optical elements to reduce Fresnel losses and internal reflections.

- Lamination Techniques: Improve mechanical strength without degrading optical clarity, often incorporating sacrificial layers for abrasion protection.

- Pressure Compensation: Some systems integrate fluid-filled cavities or flexible membranes to balance internal and external pressure without distortion.

Standards and Qualification Protocols

Marine-grade optical components are frequently qualified to meet stringent performance and durability standards:

- MIL-STD-810: Simulates environmental stresses including vibration, temperature cycling, and salt fog exposure.

- MIL-PRF-13830B: Specifies optical surface quality, including scratch-dig specifications and coating durability.

- STANAG 4370: NATO standard for environmental testing of defense equipment, applicable to subsea platforms.

- ISO 9022: Defines test methods for environmental exposure of optical instruments.

- ABS and DNV-GL: Class society rules for underwater systems, including pressure vessel inspection, material traceability, and fatigue testing.

Operational Considerations

Operational performance depends not just on the quality of the optics, but also on field practices:

- Maintenance Schedules: Regular cleaning and inspection prolong service life, particularly in high-biofouling zones.

- Deployment Techniques: Proper handling and storage reduce the risk of scratches, lens shifts, or coating degradation.

- Failure Modes: Include delamination, pressure cracking, seal failure, or internal fogging—each requiring specific design mitigations.

Reliable performance at depth requires a systems approach: optical quality, sealing integrity, mechanical robustness, and environmental resistance must all be engineered and validated as an integrated whole.

Trends and Research in Marine Optics

The need for improved durability, clarity, and miniaturization drives continued advancement in marine optical technology:

- Smart Optical Materials: Include tunable lenses and coatings that adapt to changing underwater light conditions or depth.

- Biofouling-Resistant Surfaces: Reduce the need for manual cleaning or antifouling chemicals on long-duration deployments.

- Gradient-Index (GRIN) Lenses: Compact lens systems offering wide-angle capability with reduced optical aberrations.

- AI-Driven Optical Calibration: Enhances real-time image correction and focus tuning, compensating for environmental variability.

- Integrated Optics: Combining imaging, lighting, and sensing into single sealed modules, reducing bulk and improving alignment.