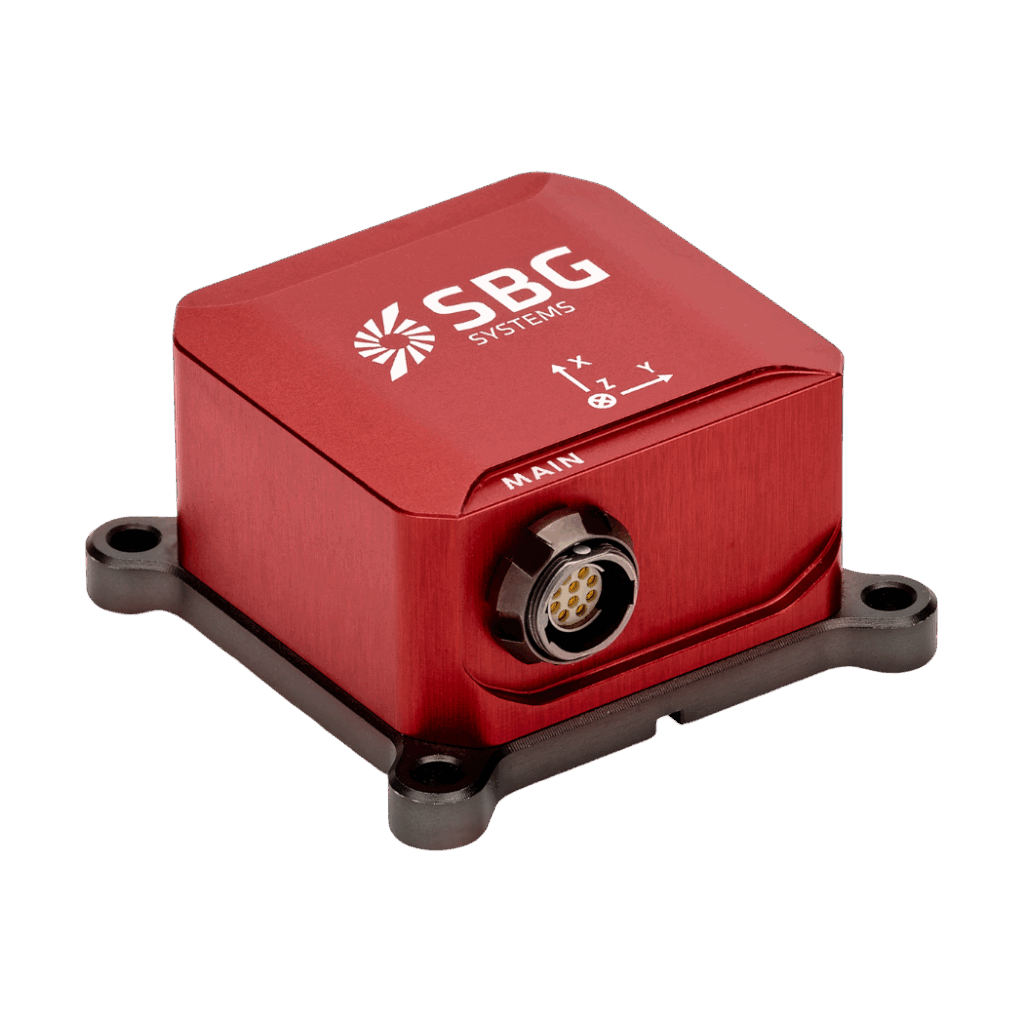

SBG Systems has introduced a new built-in vibration monitoring feature that enhances the reliability and performance of its Inertial Measurement Unit (IMU) and GNSS/INS solutions in demanding marine and offshore environments.

Vibration has long been a critical challenge for MEMS-based inertial sensors, whose internally vibrating elements are sensitive to external mechanical excitation. Excessive vibration can generate Vibration Rectification Error (VRE) and trigger resonance effects, both of which degrade navigation accuracy in applications such as seabed mapping, offshore surveying, and autonomous marine operations.

Traditionally, engineers rely on simulations and external monitoring devices, but these methods often fail to fully capture real-world conditions at the Inertial Measurement Unit‘s exact location. SBG Systems’ embedded monitoring capability eliminates this gap by delivering real-time vibration data directly from within the sensor. The system generates both full-spectrum FFT reports and simplified frequency-band summaries, providing immediate insight into vibration intensity, dominant frequencies, and potential resonance issues.

Operating up to 8 kHz with a dynamic range of 40g RMS, the module performs all processing onboard and outputs updated reports every 0.25 seconds. This enables precise correlation between mechanical excitation and inertial performance, supporting IMU placement optimization, qualification testing, payload isolation tuning, and mission-critical fault detection. By integrating vibration analytics at the source, SBG Systems transforms the IMU into a powerful dual-purpose tool for navigation and structural health insight.