FarSounder has designed its Argos Forward Looking Sonars (FLS) to be straightforward to integrate, particularly in retrofit applications. Approximately half of customer installations involve older hulls, and in some new builds the systems are added late in construction, leading the installation to be approached as a refit.

The company supports these projects with an Installation Design Guide and drawing packages that simplify the design stage for shipyards, naval architects, and integrators.

Installation Approaches

Argos Transducer Modules are adaptable to a range of hull shapes, including v-bottom, bulbous bow, and narrow stem configurations, with hoist-mounted options also available. Methods exist for vessels as varied as sailing yachts and icebreakers, ensuring there are appropriate solutions for different project requirements.

Most installations use a fixed configuration with no moving parts. This eliminates the need for hydraulic or electromechanical lift systems, reducing maintenance requirements and avoiding the space demands of lift machinery. The fairing design occupies a small footprint, and in many cases, installation can be accommodated within an existing tank, minimizing interior redesign.

For ice-classed vessels, fixed installations remain suitable if the fairing is placed below the planned ice draft.

Icebreakers, however, may require a hoist-mounted system, allowing the sonar to be retracted during active icebreaking operations. The compact Argos 350 offers additional flexibility, with the option of a fixed fairing or a hoist installation within a standard 10-inch diameter sea chest.

Review and Support Services

FarSounder provides complimentary drawing review services to confirm that installation designs meet acoustic requirements and to identify potential placement concerns. This process assists designers who may be working with forward-looking sonar for the first time.

Although each refit varies by vessel, the overall process remains similar across composite, steel, and aluminum hulls. The fairing structures are mechanically straightforward, typically making them cost-effective to fabricate at the shipyard. Since underwriters such as Lloyd’s, DNV, and ABS are familiar with Argos systems, customer drawings are usually reviewed and approved quickly.

Installation Process

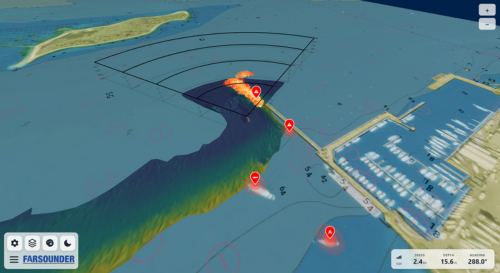

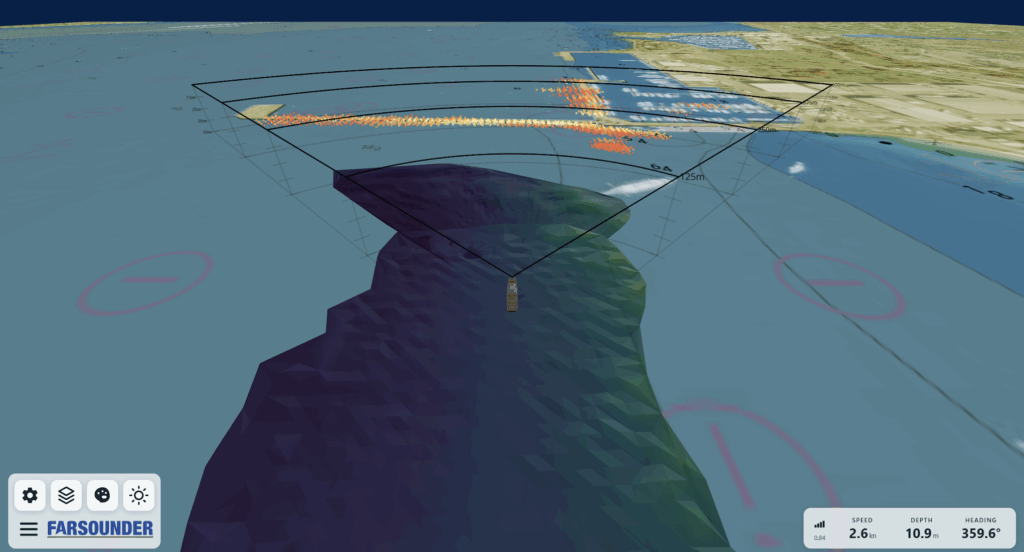

An Argos sonar system consists of three primary components: the Transducer Module, the Power Module, and a computer running SonaSoft™ software. The Transducer Module is housed in a fairing, which may be built into the hull or mounted externally, requiring only a single cable penetration. The module can be removed and replaced underwater by a diver using a wet-mateable connector.

Fairing placement is determined by hull characteristics such as shape, stem rake, and presence of a bulbous bow. Depending on these factors, the fairing may be located on the centerline through the stem, slightly forward of the stem, just off-center, or inset into the bulb.

Impact on Vessel Performance

A frequent concern relates to hydrodynamic performance. While Argos sonars appear larger than echosounders, their relative size compared to the vessel is small. Customers have not reported any changes in vessel performance before and after installation. In practice, hull coatings often have a more significant effect on drag coefficient than the addition of the sonar fairing.

Dealer Support and Implementation

FarSounder Certified Dealers manage installation, integration, and commissioning, coordinating with naval architects and shipyards to streamline the process. Customers can request installation guides and drawing packages directly from FarSounder and are encouraged to take advantage of the complimentary design review service prior to hull modifications.