Peter Baranec, the Managing Director of TACT discusses advanced machining and fabrication for maritime and defence applications, highlighting capabilities tailored to uncrewed systems, engineering support from concept to delivery, and sustainable approaches to material use and inspection.

What specific manufacturing and machining capabilities does TACT offer that best support marine, offshore, or unmanned maritime systems?

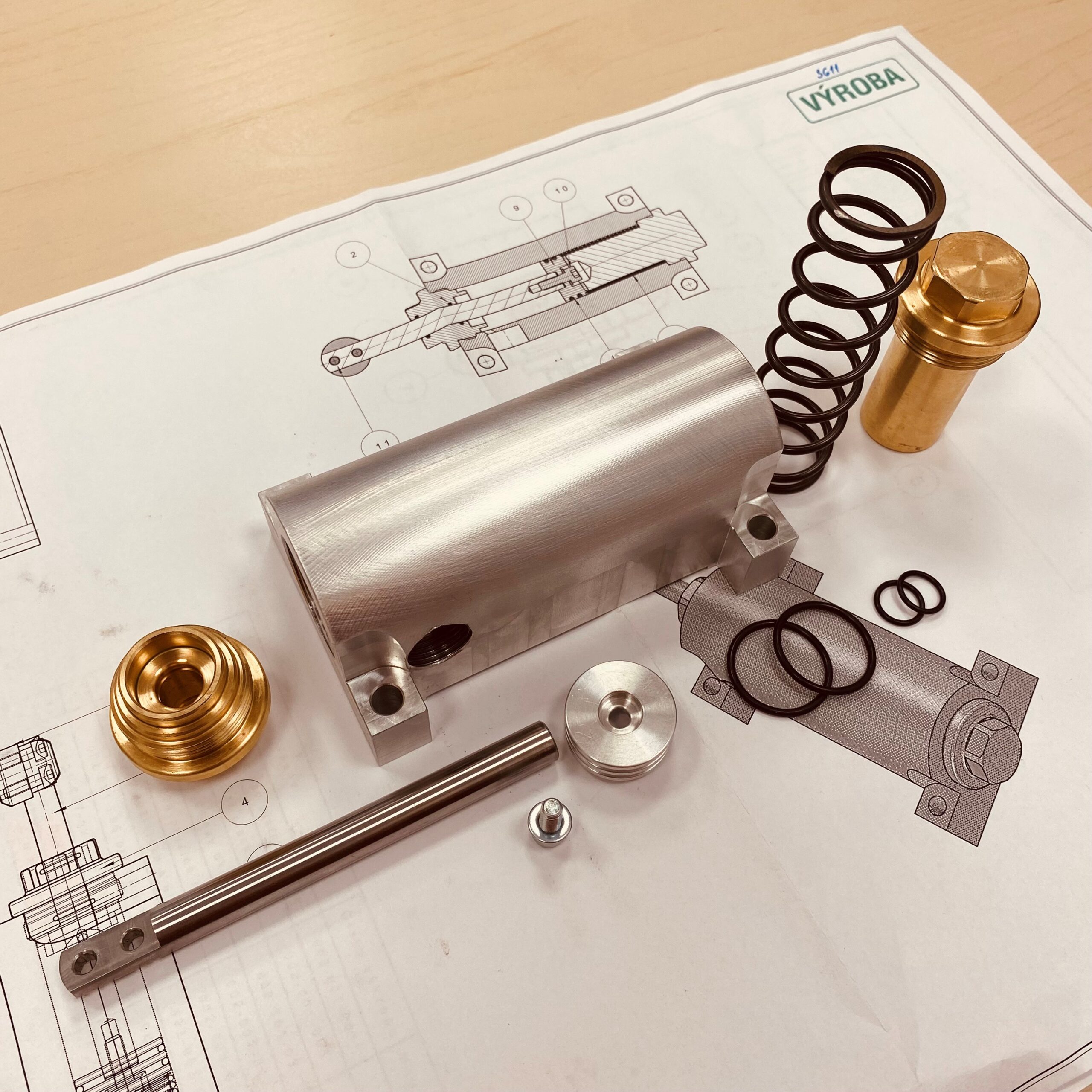

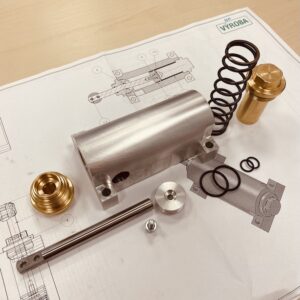

At TACT, we operate a wide range of CNC machining and fabrication equipment at our facilities in Slovakia, working with stainless steels, aluminium alloys, and technical plastics. Our capabilities include milling components up to three meters on 4-axis machines and up to six meters on 3-axis machines, turning parts as large as 3.5 meters, and carrying out high-precision boring and drilling for internal cavities and channels. We also provide surface and rotational grinding to achieve smooth finishes while maintaining dimensional accuracy.

Our welding and finishing services cover certified MIG and TIG welding, along with surface and heat treatments to enhance corrosion resistance. We also apply wet and powder coatings to protect components exposed to harsh marine conditions. Beyond machining and welding, our team assembles mechanical systems of up to 5,000 kilograms, supported by high-accuracy 3-D measurement tools that verify dimensions and tolerances at every stage. Our production capabilities have been developed with uncrewed surface vessels (USVs), remotely operated vehicles (ROVs), and autonomous underwater vehicles (AUVs) in mind, allowing us to deliver robust, reliable components for commercial, industrial, and defence applications.

Beyond fabrication, how does TACT support clients in engineering consulting, material selection, and prototyping for marine and defence engineering applications?

We support clients throughout the entire project lifecycle, offering consulting and engineering expertise to ensure specifications, tolerances, and performance requirements are met. Because we work daily with stainless steels, aluminium alloys, and technical plastics, we can directly recommend materials that balance corrosion resistance, weight, and mechanical performance. For example, engineering plastics like POM are well suited to subsea tools due to their corrosion resistance, recyclability, and lightweight properties, while aluminium alloys provide strength and durability where required.

Every project is supported by full traceability, with documentation detailing the raw-material origin and heat-treatment certificates. Our prototyping process is underpinned by high-accuracy 3-D measurement equipment, enabling us to verify early iterations and refine designs quickly. With nearly three decades of experience, our team is agile enough to support low-volume prototypes and small runs before scaling to full production.

How does TACT address environmental sustainability (material sourcing, energy efficiency, recycling) when serving ocean‑related industries?

We are in the process of implementing a total quality management system that integrates ISO 9001 and ISO 14001. ISO 14001 in particular will help us manage our environmental impact systematically, improve energy efficiency, and reduce waste across operations. To support responsible sourcing, clients receive raw-material origin and heat-treatment certificates with every project, ensuring transparency.

We also recommend the use of recyclable engineering thermoplastics such as POM, PC, ABS, and PP. These materials are lightweight, corrosion-resistant, and recyclable, reducing environmental impact while maintaining performance. Aluminium alloys are another sustainable choice, being fully recyclable and offering a high strength-to-weight ratio that can help reduce vessel weight and fuel consumption. In addition, we apply surface and heat treatments, as well as protective coatings, to extend component lifespan and reduce resource consumption over the long term.

Can you share a specific case in which you delivered components critical to AUV, ROV, or USV operations, and what lessons or innovations emerged?

I recently worked with a European marine‑robotics client developing a compact inspection ROV. We were tasked with delivering lightweight, corrosion‑resistant housings and thruster components. After reviewing the design, I selected an aluminium alloy for the main housing and POM for the thruster nozzles, materials commonly used for their corrosion resistance and durability.

The housings were milled on our 4‑axis machines and then anodised and powder coated to maximise corrosion resistance; subsea housing design guidelines emphasise using both coatings and cathodic protection to combat corrosion. Thruster nozzles were machined from POM, which is lightweight and does not require external lubrication.

Throughout prototyping, our high‑accuracy 3‑D measurement tools ensured the components met tight tolerances and achieved watertight sealing. Working side‑by‑side with the client on material selection and surface finishing shortened the development cycle. The project reinforced for me the importance of early collaboration, appropriate material choice and careful surface treatment to ensure subsea reliability.

How do you manage inspection workflows across varying sizes, from small ROV parts to welded structures nearing assembly weight limits?

Inspection and measurement are central to our quality assurance process, regardless of component size. For both small precision parts and large welded assemblies, we use high-accuracy 3-D metrology tools to verify dimensions and tolerances. Our inspection protocols follow strict calibration standards using certified gauges to ensure consistency.

Our welding teams are certified to STN EN ISO 9606-1 standards, covering both TIG (process 141) and MIG (process 135) welding. In addition, we are working toward certification in non-destructive visual testing (VT 1 & 2), which will expand our inspection capabilities for larger welded structures. For assemblies weighing up to 5,000 kilograms, we combine these welding standards with dimensional checks to confirm structural integrity. Every inspection report includes raw-material origin, heat-treatment certificates, and 3-D measurement data, giving clients complete traceability and confidence in the quality of every component.